Magnetic Roll Separator

Product Details:

Product Description

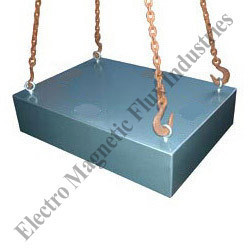

We have uniquely positioned ourselves as a dependable firm, occupied in manufacturing, exporting and supplying a commendable array of Magnetic Roll Separator. Well known for its outstanding magnetic power, this separator is used in several industries for the continuous extraction of small magnetic particles from the bulk materials. In order to provide flawless separator to the clients, our quality experts stringently check it against numerous parameters. Besides, clients can avail this rigid Magnetic Roll Separator from us at competitive price.

Additional Information:

New generation of magnetic roll separators, designed by EMF, combines the latest technological achievements in magnetic concentration based on High-intensity, High grade, high power RE- permanent magnets generate an exceptionally high magnetic gradient for the most cost-effective way to process weakly magnetic materials. Optimal separation of the material is achieved by custom design and any number of roll concentrator modules may be used to attain the required throughput or separation.

Dry granules of the material are fed onto short conveyor belts of thin yet durable material passing over rolls of customized magnetic configuration. The non-magnetic particles fall freely off the end of the roll while the magnetic particles adhere momentarily to the roll and are discharged into a separate chute by means of an adjustable splitter below the belt. The modular nature of the emf enables any number of units to be stacked to achieve the required performance.

Since the material is never in contact with the magnetic roll there is no wear on the magnets and under normal conditions magnetic strength is retained indefinitely.

Process Applications

- Andalusite and pyrophyllite beneficiation

- Beach sands beneficiation

- Bauxite cleaning

- Ceramic raw materials cleaning

- Chromites recovery

- Copper-nickel ore pre-concentration

- Diamond beneficiation

- Diatomaceous earth cleaning

- Glass sand beneficiation

- Feldspar cleaning

- Flint clay beneficiation

- High-purity quartz cleaning

- Yemenite recovery

- Iron and manganese ore beneficiation

- Kainite cleaning

- Limestone and dolomite cleaning

- Magnesite beneficiation

- Metal recovery from waste

- Quartz silica

- Refractory raw material cleaning

- Wollastone beneficiation

- Zircon cleaning

Advantages:

Compared with electromagnetic induced roll separators, the emf- PERMagROLL has:

- Lower installation costs

- Lower maintenance costs

- Lower capital costs and operating costs per tones of product

- Easy access to dust generation points

- Ready observation of the operation and ease of process control

- Reduced periodic cleaning and downtime.

- The latest emf- PERMagROLL models incorporate special new design of development and operational experience.