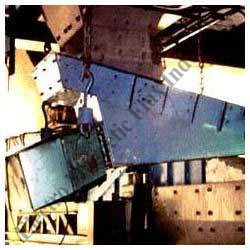

Electromagnetic Feeders

Product Details:

Product Description

With the support of our unmatched business ethics, work ability and a crew of smart professionals, we are actively committed towards providing an excellent quality Electromagnetic Feeders. Robust in design, these feeders are capable of conveying bulk materials from one place to another. Well known for their high efficiency, durability and low maintenance cost, these feeders are highly appreciated among our clients who are situated across the nation. In order to fulfill the variegated needs of our prestigious clients, we provide these Electromagnetic Feeders in customized options and at most affordable rates.

Additional Information:

We offer a range of vibratory feeders that are available in numerous models with capacities ranging from 10 to 500 tons per hour, based on dry sand weighing 50 kgs per cubic foot. The capacities vary drastically and depend on:

- Material density

- Trough liner type

- Trough length

- Trough width

- Hopper transitions

- Skirt board arrangement

| Industries Catered | Food Mining Cement Refractory Iron ore Coal feeding Feed Chemical Pharmaceutical |

| Typical Applications | Flow-extraction from silo / hopper Flow-regulation for weighing equipment Flow-feeding for / in process lines |

| Electromagnetic Feeder Features | Dust-tight and maintenance-free drive units Above- or below-deck drive units Two-mass, spring-connected, sub-resonant tuned High frequency - 3600 VPM at 60Hz Stroke - 0.060 inches Stroke generated by creating a magnetic field Suspension mount, base mount or combination of both Bolt-in replacement trough liners Multiple-drive unit feeders available |

For both electromagnetic and electromechanical feeders, following wear-resistant liners are available:

| T-1A | AR-400 | AR-500 | Stainless Steel |

| UHMW | Rubber | Ceramic | Overlay |