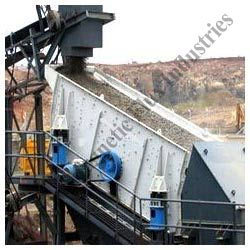

Dewatering Vibrating Screen

Product Details:

Product Description

Being a client-centric firm, we are occupied in providing a distinct collection of Dewatering Vibrating Screen. Broadly demanded in minerals, quarry, building materials, and other similar industries, this screen is used to segregate the oversize particles for re-crushing. At our well equipped manufacturing unit, this vibrating screen is fabricated from the finest quality raw materials and advance technology under the guidance of our skilful professionals. Also, our prestigious clients can avail this Dewatering Vibrating Screen from us in customized options at nominal prices.

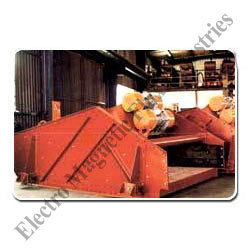

This is one of our most versatile products which has a feed end, declined at 45° and the main deck inclined at 5°. This allows a thick bed to build & trap small particles. This allows simple drainage of water without carrying small particles through openings. It is one of the best dewatering screens available in the market. We strive to better this simple drive arrangement on larger horizontal & inclined de-watering screens.

This provides the advantage of reduced maintenance, compactness and simplicity. Its drive mechanism produces a linear (straight line) motion while developing high acceleration ("g" forces). This augmented acceleration & reverse incline deck configuration is ideal for all dewatering applications. These dewatering screens can be fitted with elective electric counter-weighted motors and other features.

| Advantages | No external drives, with v-belts or cordon shaft No oil bath oscillators, with synchronizing gears and oil leaks No Motor support stand, or overhead structure for motor support No snubbers-the screens -mounted drive has eliminated the need for snubbers to reduce damage to vee-belts and external motors during the large oscillations that normally occur during stopping. Due to the absence of gears and vee-belts, the units use less power than conventional drives. Minimized maintenance time due to simple arrangement of drive Compactness-screens can be positioned very closely with a minimum of space wastage. |

| Features | Individually replaceable cross members Angle runner system for polyurethane modular unit. Flat bar runner system for woven wire decks Automatic alignment of tensioning bolts for side tensioned woven wire decks Built-in-lined feed boxes and discharge lips Stress relieving technology in design Multiple design of screening surface available |

| Optional Accessories | Sail or Ceramic-Lined Feed Box Assembly UHMW-Lined Effluent Pan Assembly Support Base Modular, Snap-In Polyurethane or Stainless Steel Screen Panels A-Frame Motor Support Base Twin electric counter weighted motors instead of pulley drive mechanism |